Research Facilities

The Department has four floors of dedicated serviced laboratories containing a wide range of analytical equipment to enable cutting-edge research in a broad range of disciplines. Of these laboratories, nine are designated as Small Research Facilities (SRFs). The Small Research Facilities are run within the Department and are also available for use by external parties.

For more information, please contact the Lab Managers Team at es-technical-staff@maillist.ox.ac.uk.

Small Research Facilities

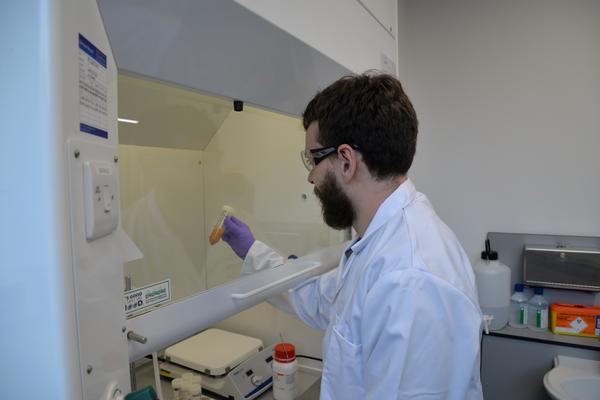

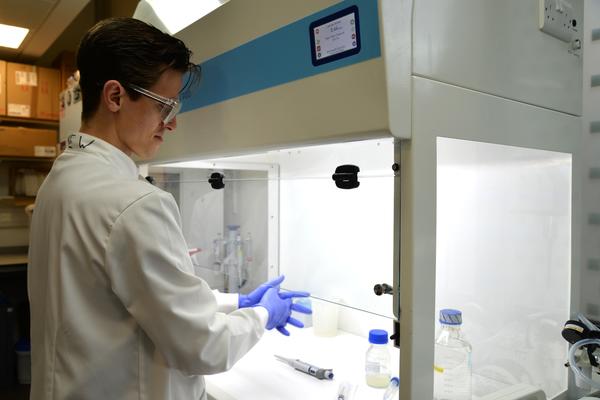

The Clean Suite Facility consists of 10 Class 10,000 (ISO Class 7) metal-free laboratories each fitted with 5 Class 100 (ISO Class 5) laminar flow/exhaust hoods and a fume hood. The facility is used for:

- Ultra-clean metal-free preparation of a variety of sample materials for trace metal concentration and high precision trace metal isotope ratio analysis.

- Cleaning of plastics for ultra-clean sample collection and processing.

- Sub-boiling distillation of ultra-pure mineral acids and other laboratory reagents.

- Production of ultra pure water (18.2 MΩ·cm).

The Department of Earth Science houses a CAMECA SX-5 FE electron microprobe.

It is equipped with a field emission gun, five wavelength-dispersive detectors, and one energy-dispersive detector (EDS). It can conduct major, minor, and trace elemental analysis of elements from carbon to uranium at sub-micron length scales on a wide variety of solid samples. We are experienced in analysing geological samples, including volcanic glasses and minerals, experimental run products, and metal alloys. Typically, samples are mounted in vacuum-tolerant epoxy resins or conductive Bakelite (metal alloys) and polished prior to analyses. Analytical detection limits vary according to a variety of factors, but are typically around 100 ppm and up for multi-element analyses. We have a good deal of experience modelling the electron beam and X-ray interactions that occur during analysis and can advise on methods to maximise spatial and analytical resolution. Actual performance of both analytical precision and sample volume will depend on the sample itself so please do get in touch if you are interested.

For rates, or to schedule use, please contact Andrew Matzen.

Fourier-Transform infrared (FTIR) spectroscopy is a simple method used to study the interaction of matter with the incident infrared beam. FTIR is a very conventional method in the study of biogenic or organic material due to the high efficiency with which the bonds in H-C-O functional groups absorb IR radiation, but it is also commonly used to ID minerals, map H-C distribution within them (i.e. melt/fluid inclusion work) and may be useful to determine the nature of other inorganic compounds (i.e. diffuse reflectance of powdered samples). We provide analytical services for users both within and beyond the University of Oxford.

Our facility can offer analysis using a Perkin Elmer Frontier spectrometer (with a KBr window) and a Spotlight 200i microscope which uses an MCT-type detector (normally cooled with liquid N2), both installed in 2017. These instruments allow studies of samples both in powdered form as well as in-situ (i.e. as thin-sections or thick specimens provided the topography is reasonable).

The instrument operates at spectral resolutions of 1-4 cm-1, stage resolution of ~1 um and the microscope apertures enable analysis of areas as small as 1x1 um. As the stage is motorized, it enables highly accurate spatial mapping surveys of heterogeneous samples. The PC station is equipped with Perkin Elmer's Spectrum software for instrument control and data interpretation. The package contains several proprietary databases of polymers, as well as allowing the import of own reference data (i.e. from open databases like RRUFF).

The Geological Facilities comprise a mixture of lab facilities, including:

- Optics Lab

- Compactor Rock Storage

- Rock Crushing

- Rock Preparation Suite

- Rock Thin Sectioning

- Rock Cutting

- Polishing Laboratory

- Minerology Laboratory

- Elementary Laboratory

- Wet Chemistry

- Sedimentology and Mineral Separation

- Mudrock Observatory

For more information please contact Emily Donald.

Inductively Coupled Plasma Mass Spectrometry (ICP-MS) is a powerful inorganic technique that resolves the abundance of many chemical elements in a wide variety of sample media, to extremely low detection limits and wide concentration ranges.

The driving force behind this high performing and versatile technique is the high temperature argon plasma, which is hot enough to excite most elements within the periodic table into ions. These charged particles are then focussed into a tight beam within the instrument and filtered by mass:charge to provide rapid (near simultaneous) determinations. The Trace Element ICP-MS Small Research Facility has two ICP-MS instruments, one with a magnetic-sector mass spectrometer and another with a quadrupole mass spectrometer. Both offer rapid scanning, high sensitvity and excellent resolution and detection capabilities.

THERMOFINNIGAN ELEMENT 2 ICP-MS

-

Magnetic-Sector ICP-MS with reverse Nier Johnson geometry

-

Used for high resolution and high sensitivity trace element analysis (see which elements can be measured and the likely resolution required here)

-

Ideal for ultra-trace measurements and for determinations of elements troubled by spectral interferences (see what detection limits can be acheived here)

-

Fully automated with capability to measure up to 80 samples in one run*

-

Can be coupled to our ESI Apex Omega desolvator for a further boost in sensitivity and reduction in spectral interference

*Assuming sample solutions are prepared in 2mL micro centrifuge tubes

PERKINELMER NEXION 350D ICP-MS

-

Quadrupole ICP-MS with universal cell to remove interference [uses NH3 for dynamic reactions (DRC) and He for kinetic energy discrimination (KED)]

-

Coupled with ESI PrepFAST autosampler and autodiluter

-

Flow injection capability using the ESI PrepFAST FIAS- expands capability to directly measure samples with total dissolved solids concentrations >2000 ppm

-

Ability to be hyphenated with the ESI seaFAST ion exchange system (also owned by the facility)- removes group 1 and 2 elements (notably Na, Ca and Mg) from seawaters to enable preconcentration of transition metals/REEs without the need to dilute

-

Can be coupled with our ESI Apex Omega desolvator for a further boost in sensitivity and reduction in polyatomic interference

-

Enables fast scanning at a fixed low resolution

-

Fully automated with capability to measure up to 240 samples in one run**

**Assuming sample solutions are prepared in 15mL centrifuge tubes and sample measurement times are <2 minutes

The scanning electron microscope (SEM) is used to image and analyse a range of materials from rocks, metals, biological samples and meteorites. The Department of Earth Science houses a versatile FEI Quanta 650 scanning electron microscope.

It is equipped with:

- A field emission electron source for high resolution imaging

- Secondary and Backscatter electron detectors

- An Oxford Instruments EDS system for major and minor elemental characterization and mapping

- An Oxford Instruments electron backscatter diffraction (EBSD) detector for measuring crystallographic structure of materials

For rates, training and booking information, please contact Kris Sokół.

The Stable Isotope Laboratory is equipped with a Thermo Delta V Advantage isotope ratio mass spectrometer (IRMS) coupled to a range of peripherals.

Peripherals include: i) A Kiel IV carbonate preparation device, ii) a Gasbench II & CTC Analytics auto-sampler for automated carbonate and solution isotopic analyses, iii) a Thermo Isolink CN Elemental Analyser and Conflo IV for C/N ratios, weight %C, weight %N, δ13C, δ15N. We have a carbonate roasting device and an offline gas purification line for working with less conventional samples.

We measure an abundance of marine and terrestrial carbonates (δ13C, δ18O); waters and pore solutions (δ2H, δ18O); organic matter (δ13C, δ15N, %C, %N, C/N); δ13C of dissolved inorganic carbon (DIC) in solutions; δ13C, δ18O in enamel samples for archaeology projects.

Our instruments cater for a wide range of solid sample masses (from ~ 20 to 100’s of ug) depending on sample availability and homogeneity. Solution measurements are made on 0.5 mL solution (or less, where necessary). In addition to conventional geological measurements we undertake specific projects (e.g. measuring chemical reaction rates with carefully enriched isotopic solutions). All measurement runs are tailored to user requirements and are assessed for precision and accuracy using internationally recognised standards.

For more information or to discuss measurement requirements, please contact Chris Day.

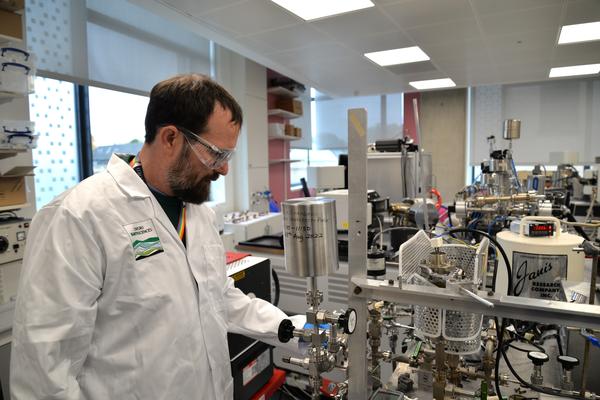

The workshop is focussed on helping internal and external research groups perform ground-breaking research by designing and producing lab and field equipment. We manufacture equipment for lab groups within the Department and University, as well as across the world.

Our Capabilities

- Precision machining including: manual turning, manual milling, surface grinding, radial drilling

- CNC milling

- CNC turning

- 3D printing

- 3D CAD/CAM facilities including: offline programming, CAD modelling, creation of working drawings, reverse engineering

- Plastic fabrication, acrylic, polycarbonate etc.

- Welding and fabrication: guillotines, sheet metal forming, bending, rolling, punching

- Electronic and electrical projects/repairs

- Material hardening

- Honing

- Bench fitting/general assembly

- Hydraulics/pneumatics

- Painting and plastic coating

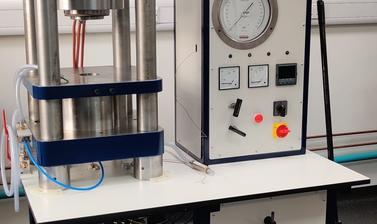

Piston Cylinders

We have been building piston cylinder apparatuses in the Earth Sciences workshop for over 15 years now. We have produced 12 that have been sent all over the world in our distinctive Oxford blue livery. Designed by Prof Bernie Wood and Mr Fred Wheeler (a former workshop colleague in Bristol) the Piston Cylinder can reach pressures of 3 GPa and temperatures of 1700 degrees celsius routinely. With care this range can be extended to 4 GPa and 2300 degrees celcius.

We also design and machine all of the consumables that are used with the Bristol style PC. Using CNC manufacturing means all of parts are machined to a precise size and will not vary allowing experiments to run smoothly. We produce consumables and accessories in sizes used for the ½ inch, 3/4inch and 1inch experiments.

We also have the capability to design and manufacture complete Salt die sets and pressure plates with hardened steel or carbide inserts.

For enquiries please contact James King.

Bridge piece, thermocouple plate and optional extras (salt die, pressure plate, thermocouple wire assembly, etc.)

Powder X-ray diffraction (XRD) is a versatile analytical method that provides important information on material properties. Powder XRD can yield the phase composition, structure, and texture of a range of solid samples, and is widely applied across the Earth Sciences.

The Department of Earth Sciences at Oxford houses a PANalytical Empyrean Series 2 powder diffractometer installed in 2015. The Empyrean is configured for a range of diffraction experiments in the theta-theta geometry, and operates with a Cobalt X-ray source, programmable divergence and anti-scatter slits, reflection-transmission spinner stage, capillary stage, parallel beam focusing mirror, and sample changer (accommodating up to 48 powder samples). The system also features a flat sample stage allowing in-situ analysis on large (unpulverized) samples provided surface flatness is reasonable. The instrument can be used in reflection or transmission geometry, and is configured with the newly developed PIXcel1D detector, which increases data acquisition rates up to ~256 times compared to conventional single strip detectors. Through the use of silicon single crystal substrates, diffraction data can be acquired on vanishingly small amounts of material (though this is dependent on composition).

Powder diffraction data produced from our facility are interpreted in a number of different ways, depending on the application and nature of the material. The laboratory uses PANalytical's HighScore software to perform phase identification and quantification (including clay mineral identification) sourcing reference data from the International Centre of Diffraction Data (ICDD)'s latest (2023) database - access to which is possible on request (see 'Remote Access' section below). Structural refinement using the Rietveld method as well as size/strain analyses or in-situ/non-ambient diffraction are also possible.